Contributing Editor: Dave Davidson, Deburring/Finishing Technologist | 509.230.6821 | dryfinish@gmail.com | https://about.me/dave.davidson

If you have parts that need edge or surface finishing improvement and would like to have FREE sample part processing and a quotation developed for finishing the parts please contact Dave Davidson at dryfinish@gmail.com I can also be reached at 509.230.6821. Information about equipment for bringing Centrifugal Iso-Finishing capability to your facility is also available…

If you have parts that need edge or surface finishing improvement and would like to have FREE sample part processing and a quotation developed for finishing the parts please contact Dave Davidson at dryfinish@gmail.com I can also be reached at 509.230.6821. Information about equipment for bringing Centrifugal Iso-Finishing capability to your facility is also available…

Not all burrs are created equal. Some burrs are heavily rooted and some materials have a measure of plasticity. These kinds of materials can pose a severe burr removal challenge for conventional mass finishing systems and require use of a high intensity and high energy finishing process such as centrifugal barrel finishing. SEE:

Contrast the burr (edge) and surface condition of the top picture (finished) with that of the picture of the part prior to centrifugal iso-finishing (bottom picture)

Below are some process video footage demonstrations of high-speed centrifugal isotropic finishing. These automated edge and surface finishing methods are capable of producing very refined low micro-inch surfaces that can improve functional part performance and service life.

Isotropic Micro-Finishing Part Photography by Mark Riley, BV Products

Centrifugal isotropic finishing

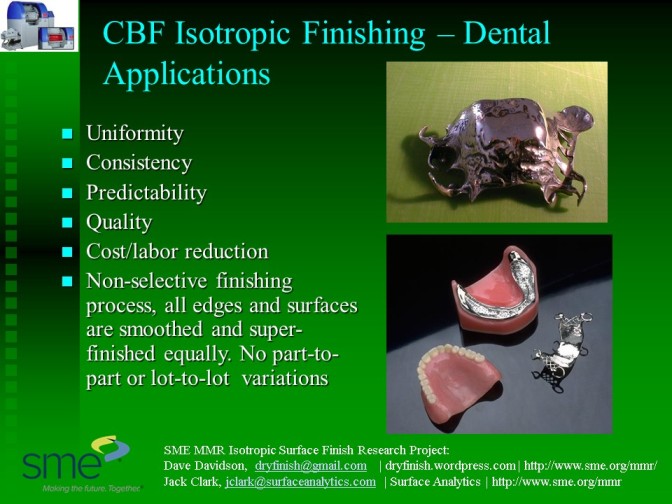

Centrifugal barrel finishing (CBF) is a high-energy finishing method, which has come into widespread acceptance in the last few years. A long list of important CBF applications have been developed in the last few decades.

Similar in some respects to barrel finishing, in that a drum-type container is partially filled with media and set in motion to create a sliding action of the contents, CBF is different from other finishing methods in some significant ways. Among these are the high pressures developed in terms of media contact with parts, the unique sliding action induced by rotational and centrifugal forces, and accelerated abrading or finishing action. As is true with other high energy processes, because time cycles are much abbreviated, surface finishes can be developed in minutes, which might tie up conventional equipment for many hours.

The principle behind CBF is relatively straightforward. Opposing barrels or drums are positioned circumferentially on a turret. (Most systems have either two or four barrels mounted on the turret; some manufacturers favor a vertical and others a horizontal orientation for the turret.) As the turret rotates at high speed, the barrels are counterrotated, creating very high G-forces or pressures, as well as considerable media sliding action within the drums. Pressures as high as 50 Gs have been claimed for some equipment. The more standard equipment types range in size from 1 ft3 (30 L) to 10 ft3, although much larger equipment has been built for some applications.

Media used in these types of processes tend to be a great deal smaller than the common sizes chosen for barrel and vibratory processes. The smaller media, in such a high-pressure environment, are capable of performing much more work than would be the case in lower energy equipment. They also enhance access to all areas of the part and contribute to the ability of the equipment to develop very fine finishes. In addition to the ability to produce meaningful surface finish effects rapidly, and to produce fine finishes, CBF has the ability to impart compressive stress into critical parts that require extended metal fatigue resistance. Small and more delicate parts can also be processed with confidence, as the unique sliding action of the process seems to hold parts in position relative to each other, and there is generally little difficulty experienced with part impingement. Dry process media can be used in certain types of equipment and is used for light deburring, polishing, and producing very refined isotropic super-finishes.

AUTHOR BIOGRAPHY – David A. Davidson, [dryfinish@gmail.com]

Mr. Davidson is a deburring/surface finishing specialist and consultant. He has contributed technical articles to Metal Finishing and other technical and trade publications and is the author of the Mass Finishing section in the current Metal Finishing Guidebook and Directory. He has also written and lectured extensively for the Society of Manufacturing Engineers, Society of Plastics Engineers, American Electroplaters and Surface Finishers Association and the Mass Finishing Job Shops Association. Mr. Davidson’s specialty is finishing process and finishing product development.

Mr. Davidson is a deburring/surface finishing specialist and consultant. He has contributed technical articles to Metal Finishing and other technical and trade publications and is the author of the Mass Finishing section in the current Metal Finishing Guidebook and Directory. He has also written and lectured extensively for the Society of Manufacturing Engineers, Society of Plastics Engineers, American Electroplaters and Surface Finishers Association and the Mass Finishing Job Shops Association. Mr. Davidson’s specialty is finishing process and finishing product development.

Contributing Editor: Dave Davidson, Deburring/Finishing Technologist | 509.230.6821 | dryfinish@gmail.com | https://about.me/dave.davidson

If you have parts that need edge or surface finishing improvement and would like to have FREE sample part processing and a quotation developed for finishing the parts please contact Dave Davidson at dryfinish@gmail.com I can also be reached at 509.230.6821. Information about equipment for bringing Centrifugal Iso-Finishing capability to your facility is also available…

If you have parts that need edge or surface finishing improvement and would like to have FREE sample part processing and a quotation developed for finishing the parts please contact Dave Davidson at dryfinish@gmail.com I can also be reached at 509.230.6821. Information about equipment for bringing Centrifugal Iso-Finishing capability to your facility is also available…

What was the cycle time for these parts? I’m curious… thanks Dave

LikeLike

Two steps: 20 minutes with a high density plastic media in, and 20 minutes in a dry polishing cob. It would be very difficult to duplicate this in a vibratory machine. Just not enough force.

LikeLike

LikeLike

Geeze, I can’t seem to embed an image here for purposes of sharing – Im going to have to edit these comments, is there anyway too do that?

LikeLike

LikeLike